Description

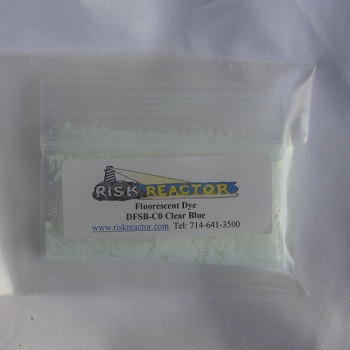

DFSB-C05G Five Grams of Clear and Invisible UV Blue Dye Description:

Risk Reactor Inc’s DFSB-C0 Clear Blue Fluorescent Dye for solvent based mediums. DFSB-C0 has a very strong fluorescent effect for use in invisible inks, security paper printing, inks, special effects, markings, coding applications, and paints. Clear Blue Fluorescent Solvent Based Dye. Our DFSB-C0 is one of the most popular clear blues because of its strong fluorescent color and unique characteristics. When in solution the dye will be invisible in regular light, fluorescent blue under a black light. Perfect for Non Destructive Testing or where a visible stain is not desired.

Ordering Information for the DFSB-C05G:

You can order online 24 hours a day to receive your DFSB-C0 (Clear Blue Fluorescent Dye) or simply print and complete the Order Form found on our website, then fax or email it back to us. The Order Form is located at the end of our product list. We can also offer quotes on large volumes and we do ship all around the world.

DFSB-C05G Fluorescent Dye Product Introduction.

Risk Reactor Inc's Clear Fluorescent Blue Dye is stable, light fast and can be used with a variety of solvents. It is used in security inks, paints, coatings, glue, adhesives, tracing, and other applications. Our DFSB-C0 Clear Blue is used in numerous applications and is one item to always include with your order. Clients also use this dye to add to other pigmented mediums to add depth, color, brightness, or a dual effect. For Non-Destructive Testing purposes the DFSB-C0 is the workhorse used by it or in addition to other colorants. This is a light colored powder that when dissolved completely it is absolutely clear or invisible to the naked eye and will show an intense bright color under Risk Reactor Black Light. The color can shift from blue to white depending on the concentration in your medium.

Benefits of Risk Reactor Inc's DFSB-C05G Clear Fluorescent Blue Dye:

- Good light fastness

- FDA approved for use in polymers, resins or adhesives intended for food contact applications, or in lubricants with incidental food contact

- Brilliant bluish white fluorescent effects

- High chemical stability

- Readily soluble in a wide range of organic solvents

- Excellent resistance to heat

- Fluoresces very brightly

- Absolutely CLEAR when dissolved

- Used in conformal coatings and fugitive glue applications

- Used in thermoplastics, coatings, printing inks, man-made fibers and as a tracer

- Incredibly strong fluorescent effect

DFSB-C05G Applications:

DFSB-C0 Clear Blue Fluorescent Dye is used in solvent based paints, fugitive adhesives, thermoplastics, coatings, printing inks, security inks, anti-counterfeiting inks, man-made fibers, and as a tracer. DFSB-C0 can be used in food packaging applications and is subject to provisions of Title 21, Code of Federal Regulations, Sections 175.105,178.3297. It can also be used in adhesives, olefin polymers, polystyrene and rubber-modified polystyrene, polyvinyl chloride, polyacetal, and polycarbonate.

Risk Reactor Inc’s DFSB-C05G is used in:

Food Packaging

Thermoplastics

Coatings

Tracing

Conformal Coatings

Printing Inks

Man-made fibers

Special Effects

Color shifter

Candles

Household Articles

Sheeting

Coating Coverage

Fugitive Glue Application: Simply add this dye to any glue or adhesive that the dye will be soluble in. This is a very strong fluorescent dye, so a little will go a long way. The clearer the adhesive or glue, the less you will need to see it. Final loadings of the DFSB-C0 Clear Blue Fluorescent Dye can be as low as .0001%. Risk Reactor Inc also carries water-based additives, such as product codes IFWB-C0 and DFDRY, among many others. See our Fluorescent Dyes Water Based for more information.

Coating Coverage: DFSB-C0 Clear Blue Fluorescent Dye provides an excellent means to determine coverage of either conventional or UV cure coatings. Small amounts act as a tracer, which when viewed under a Risk Reactor Black Light, indicating whether or not a uniform coating coverage has been achieved. This is especially useful for clear coatings, where coverage can be difficult to determine by conventional means.

Leak Application: Our Clear Blue Fluorescent Dye has been used to invisibly trace fuel leaks in aircraft fuel systems. This dye is highly concentrated and is clear when diluted. Under long wave black light activation, the tagged fuel fluoresces a strong, bright blue making it easy to find the leaks. Take some of the same fuel that will be tagged and mix the dye into it. The dye will instantly go into solution. Always do this under a black light, so you can see what you are doing. Be aware, fuel is highly flammable and any light source must be secure. The concentration level in the final loading can be .1-.0001% depending on numerous factors, such as the strength of the black light, the control of the ambient light when searching for the leak, the color of the background, etc. Use the mixed concentrate and enter into the fuel system.

Identification: DFSB-C0 Clear Blue Fluorescent Dye may be used in printing inks to facilitate the quick identification of security bonds, and also for a safeguard against forgeries, such as bank notes.

Waxes, Fats and Oils: DFSB-C0 Clear Blue Fluorescent Dye is soluble in waxes, paraffins, fats, mineral and vegetable oils, plus it may be mixed in with these substances as a solution for an organic solvent. Very small amounts of this dye effectively serve to mask the slight yellowness inherent in such products. Due to its good light fastness in organic solvents, and its low toxicity, DFSB-C0 can be added to numerous technical liquids.

Technical Information:

Molecular weight is 430.6 g/mol

Specific Gravity AF : 1.26

Solubility in Water: <0.01 % in water at 20C

Color: Yellow

Physical Form: Yellow Crystalline Powder

pH: Not applicable

Freezing/melting point: 196-203C

Decomposition Temperature: 350C

Ignition: 490C BAM

Vapor Pressure: ~2 X 10(-10) mmHg at 20C

Octanol/Water Coefficient: Log Po/w >6

% Volatile: <0.5%

Absorption Max: 375 nm

Fluorescence Max: 435 nm

Extinction Coefficient E1% 1cm: 1200 (375 nm)

Food and Drug Administration Certificate and Data Chart

This product has been cleared by the FDA for use in polymers, resins, or adhesives intended for food contact applications, or in lubricants with incidental food contact. Food additive regulation: Colorants for polymers 178.3297

|

Existing Regulations. |

Maximum Concentration. |

Foods Allowed. |

Temperatures Allowed. |

|

Adhesives complying with 175.105 |

No Restrictions. |

No Restrictions. |

No Restrictions. |

|

Pressure sensitive adhesives complying with 175.125 |

0.05% |

No Restrictions. |

No Restrictions. |

|

All polymers. |

0.015% |

No Restrictions. |

A-H |

|

All polymers. |

0.05% |

Aqueous, acidic and alcoholic foods. |

A-H |

The information provided has been compiled from Title 21 of the U.S. CFR and is believed to be reliable. It is meant only as a guide, and is not intended to replace, supplement or interpret any regulations. It is the responsibility of the user to assess its product uses and applications and assure conformance to all applicable laws and regulations.

Lightfastness in Various Substrates.

Lightfastness depends upon the type of substrate, its composition, and the stabilizers. The following lightfastness values (Blue Scale) were obtained by the Xenotest:

Polyvinyl Chloride 4 to 7

Polyethylene 2 to 4

Polypropylene 1 to 4

Cellulose Acetate 5 to 7

Polystyrene 2 to 5

Acrylic Resin Lacquers 4 to 5

Alkyd-Melamine Lacquers 4 to 5

Polyamide 3 to 5

Linear Polyester 7

How to Use UV Reactive Colorants:

DFSB-C0 is widely used in a variety of industries from tracing leaks, fugitive glue, NDT, conformal coatings, to security inks. Usually you would dissolve DFSB-C0 Clear Blue Fluorescent Dye directly into one of your components. or a compatible organic solvent (see table above for solvent to choose from) for your medium. If the latter, put your concentrate into your medium after it has been dissolved. If you have any un-dissolved dye, you have too high of a loading for that solution. We recommend using Risk Reactor Black Lights to view the dye for inspection, effect, or manufacturing line.

This is a light colored powder, that when dissolved completely, it is absolutely clear or invisible to the naked eye. The color will show up with an intense bright response under Risk Reactor Black Light. The color can shift from blue to white depending on the concentration in your medium. White color being a higher loading of dye while a blue color is a low loading.